Mobile Warehouse

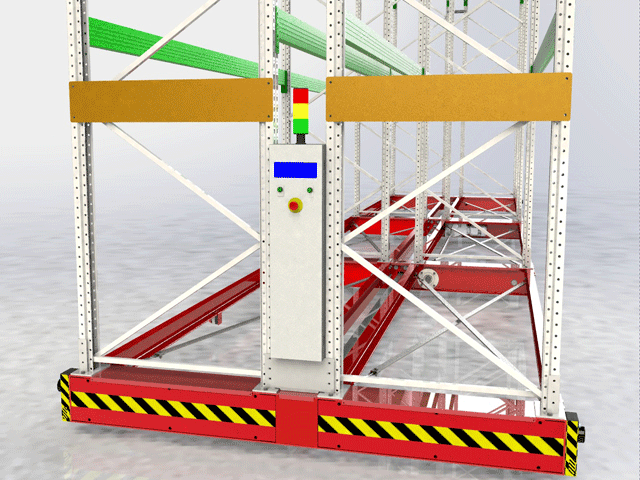

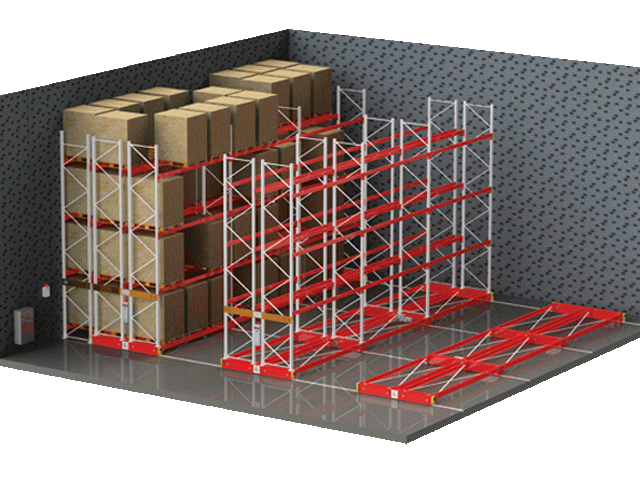

It is a kind of storage system that allows to increase the capacity of the warehouse and can move in the direction of the corridor in blocks.

Usage Areas

High volume production plants

Cold Air Food Warehouses (cutting chicken producers etc.)

Plastic Injection manufacturers

Internet Marketing Repositories

Key Features

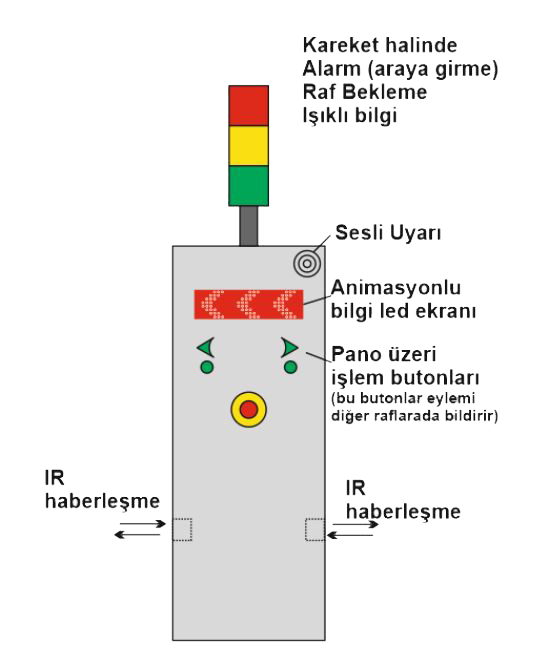

- Each rack is independent of the others and does not require an external PLC or panel,

- In an application with an average of 10 racks, only 1 supply cable is used instead of hundreds of cables required,

- Collision-free accordion movement between shelves,

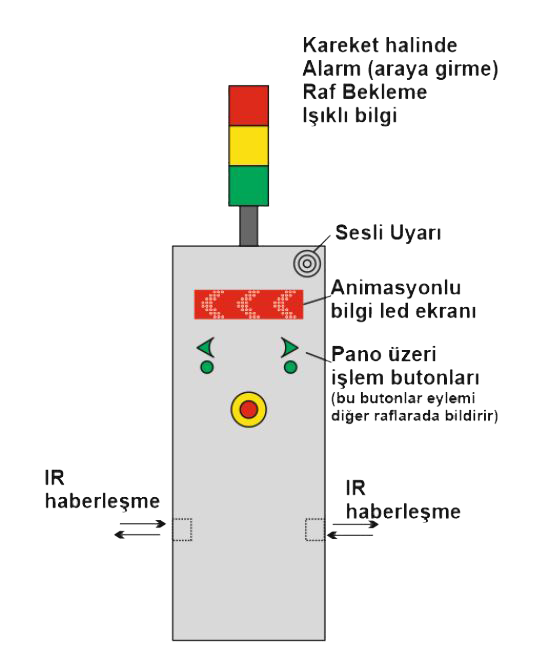

- Industrial controller for forklift operator use,

- Access over the factory network or wireless wifi thanks to the Ethernet connection. Warehouse management software support,

- Wireless IR communication between racks,

- Wireless RF (radio frequency) communication between shelves,

- Up to 4 motor driver outputs for each shelf,

- Control via Android software (can be used on mobile phone as remote),

- night mode,

- Authorization support,

- Control and adjustment of rack numbering and sensors from the computer during installation,

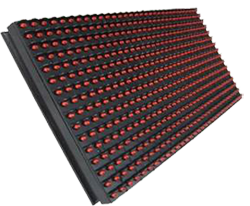

- Large size led information board per shelf,

- Operation and fault records (200,000 operations).

Mobile Warehouse

It is a kind of storage system that allows to increase the capacity of the warehouse and can move in the direction of the corridor in blocks. Our electronic system, which we have patented in 2012 and which adjusts the positions of the shelves by communicating with each other through infrared communication and/or wireless communication, is an integrated product with more than 200 mobile warehouse applications for 4 years and all field experience.

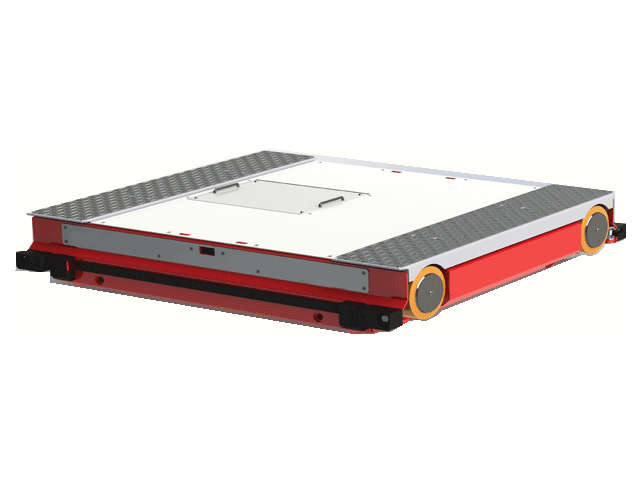

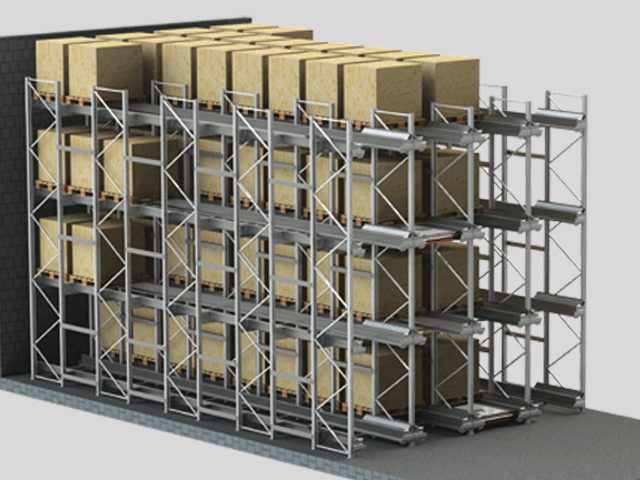

Mobile warehouse racking systems are a system in which shelves are built on a mobile base, plinth, and guided by rails on the floor. Driven by an electric motor, the mobile base-to-base moves along the tracks to open one or more access aisles. These products, which can store heavy loads, are also an extremely compact storage solution.

|

|

|

|

| Each shelf moves left and right, leaving enough space for a forklift to enter, while the other shelves are placed adjacent. Shelves communicate among themselves and provide coordination. | With the Android-based application, access is provided via wifi. |

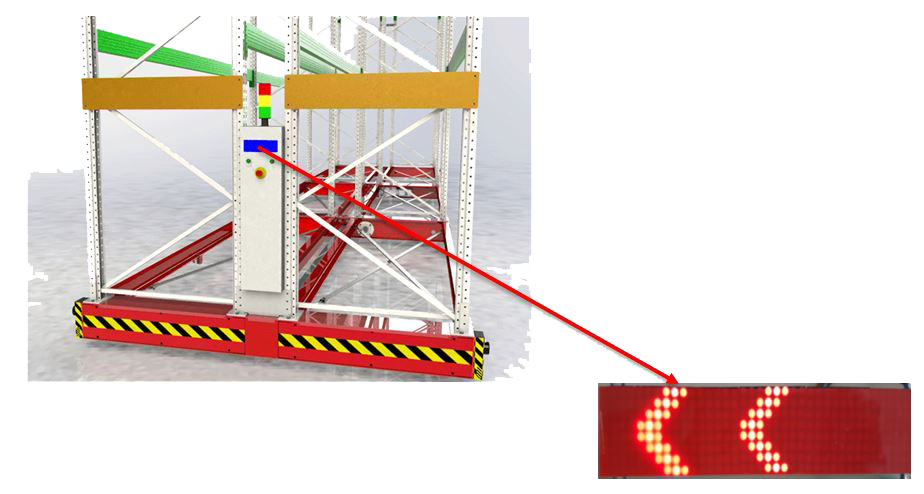

Direction information is displayed on the led screen during the movement of the shelves, and in case of alarm, the warning information is displayed on the led screen.

Shelf Head Large Size Information Board

The led animation panel can be placed at the beginning or end of the shelf and can show informational messages such as please do not enter during movement.

It is placed on the 1st shelf or the last shelf in the warehouse, facilitating the operator's shelf tracking.

When there is no work, the display turns itself off after a certain time.

Connection style

Connector type that is easy to prepare and use.

Easy and fast response in case of malfunction.