Poultry Automation

KUL Poultry Automation Poultry Automation provides humidity, temperature, ammonia etc. inside and outside of the poultry house via internet and GSM/GPRS infrastructure. It provides the opportunity to read and control the heating boiler, pads and pet covers, winter flaps, fans, feeder bowls, gases (Ammonia) in the environment, and alarm notifications as SMS, short message and phone call depending on their values.

Usage Areas

Key Features

- Internal web server

- ability to e-mail

- Ability to keep sensor values of the last 120 minutes.

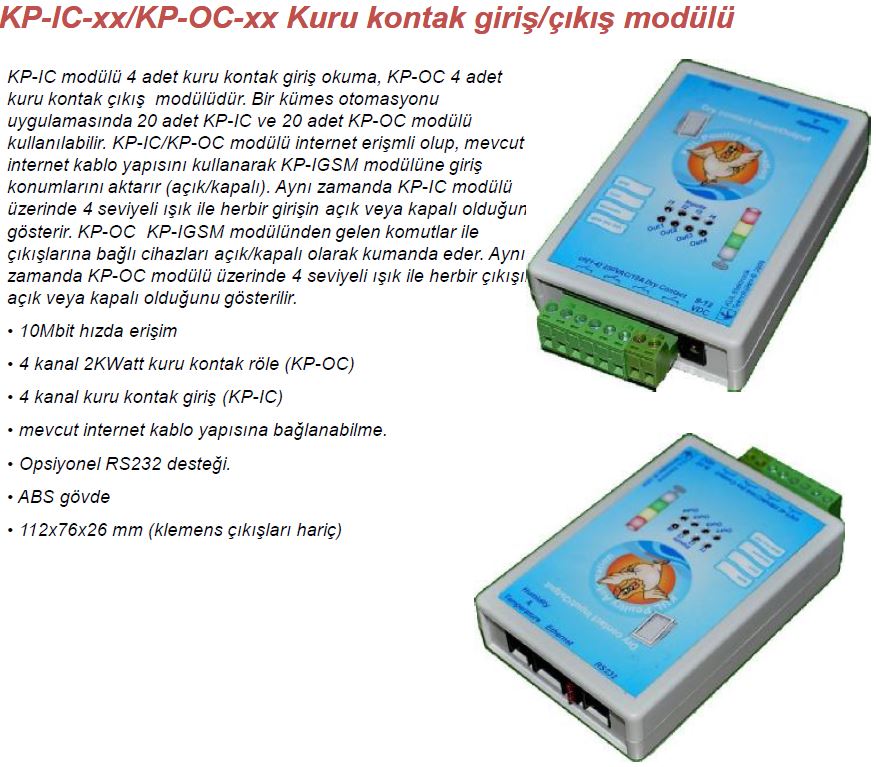

- Sensor and control modules (KP-IO,KP-IC,KP-OC,KPSA,KP-SX,KP-FC-

- gas, fire, temperature, humidity, chemicals

- Internet connection

- Internal sensor inputs

- SA,KP-SX,KP-FC-gas, fire, temperature, humidity, chemicals etc.

- Internet browsing and management (data transfer rate 10Mbit).

- Up to 5 different people, via SMS on GSM, alarm, remote

- Being able to control and program with SMS.

- Ability to make phone calls to up to 5 different people via GSM.

- Password controlled operations

- Ability to operate outputs according to sensor status,

- Ability to give a time program

- Possibility of mounting on wall or panel

- 4 Band GSM support (800,900,1800,1900 Mhz)

- Long-term recording with optional MS windows KP-SPC software

- able to hold

- Aluminum body

- Dimensions: 112.5x103.0x29.5mm, without mounting screw

Poultry Automation

KUL Poultry Automation Poultry Automation provides humidity, temperature, ammonia etc. inside and outside of the poultry house via internet and GSM/GPRS infrastructure. It provides the opportunity to read and control the heating boiler, pads and pet covers, winter flaps, fans, feeder bowls, gases (Ammonia) in the environment, and alarm notifications as SMS, short message and phone call depending on their values. All transactions can be made from a computer over the internet, or by entering the internet from a mobile phone or via SMS. In this way, intervention and information are provided over the mobile phone in case of emergency.

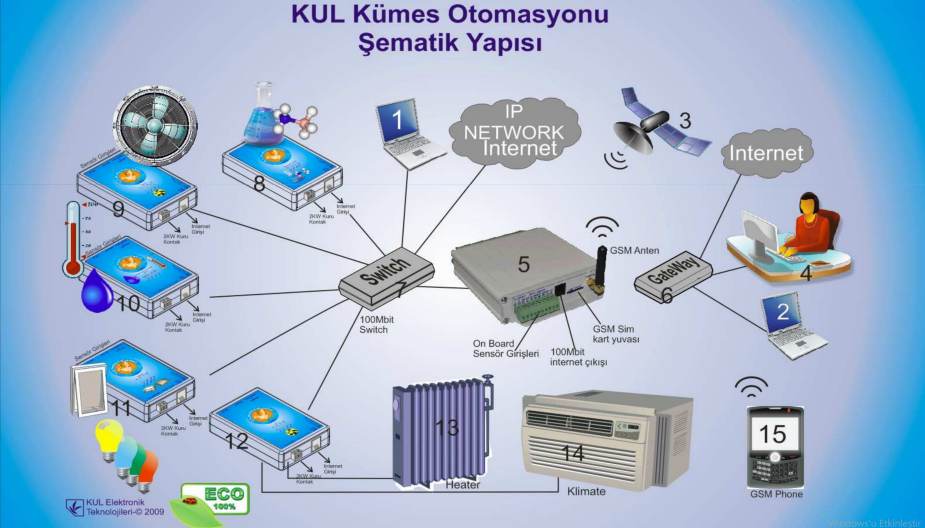

SYSTEM STRUCTURE

It shows a computer connected to the ethernet network for the building, indicated by 1 on the diagram. The poultry functions can be monitored and controlled by accessing the KP-IGSM(5) module from this computer with a web browser. At the same time, the PC software also keeps historical records on this computer. The IGSM(5) module scans the sensor network and receives or controls parameters such as temperature, humidity, gas, fan, ventilation, heating. These sensor modules are KP-SA(8) ammonia module, KP-FC(9) fan control module, KP-TH(10) temperature and humidity reading module, KP-IC(11) window, door contact input module, KP-OC (11) 2KW control module is analog sensor reading module with KP-SX(12).

Access to the house functions can be done via a mobile phone with a web browser or via SMS.

It is a singular system with many features such as low energy consumption, immunity to high magnetic field thanks to the galvanic isolation of all sensor modules, standard internet cabling structure and installation without the need for technical knowledge.