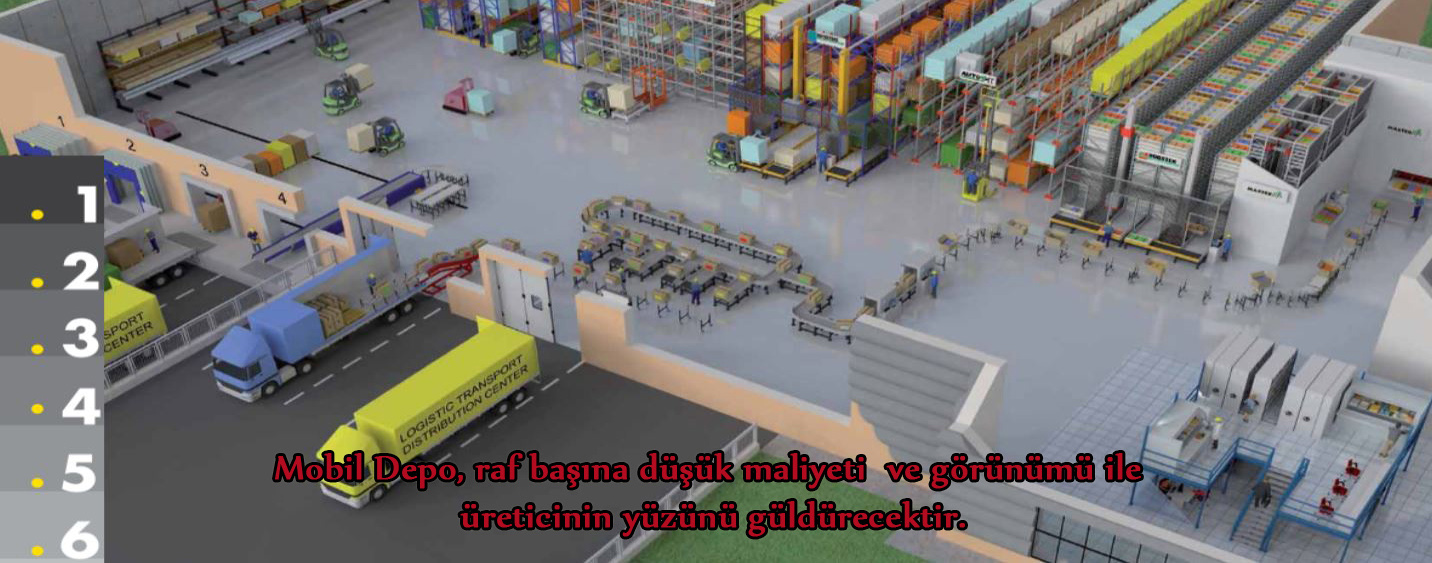

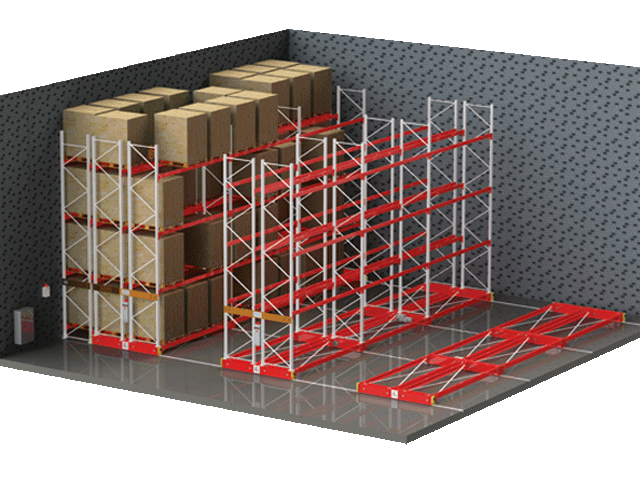

Mobile Warehouse

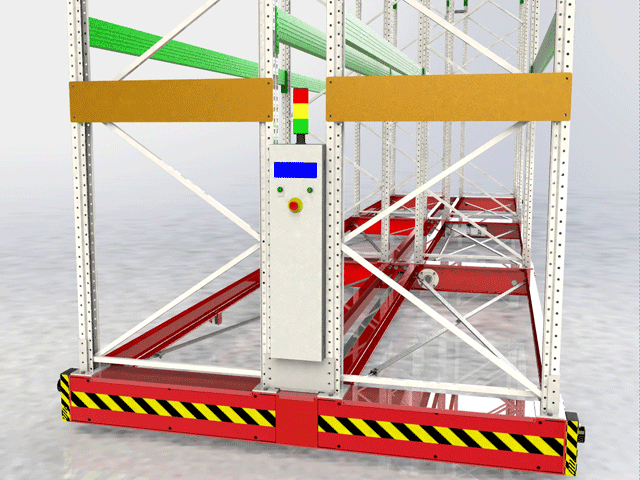

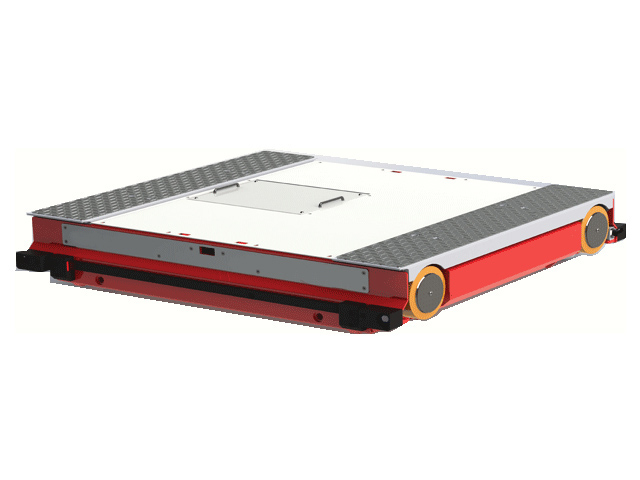

It is a kind of storage system that allows to increase the capacity of the warehouse and can move in the direction of the corridor in blocks.

Mobile Warehouse

Key Features

- Each rack is independent of the others and does not require an external PLC or panel,

- In an application with an average of 10 racks, only 1 supply cable is used instead of hundreds of cables required,

- Collision-free accordion movement between shelves,

- Industrial controller for forklift operator use,

- Access over the factory network or wireless wifi thanks to the Ethernet connection. Warehouse management software support,

- Wireless IR communication between racks,

- Wireless RF (radio frequency) communication between shelves,

- Up to 4 motor driver outputs for each shelf,

- Control via Android software (can be used on mobile phone as remote),

- night mode,

- Authorization support,

- Control and adjustment of rack numbering and sensors from the computer during installation,

- Large size led information board per shelf,

- Operation and fault records (200,000 operations).

Each rack is independent of the others and does not require an external PLC or panel, Only 1 feeder cable is used instead of hundreds of cables required in an application with an average of 10 racks, Collision-free accordion movement between racks, Industrial control for forklift operator use, In-house thanks to Ethernet connection access over the network or via wireless wifi. Warehouse management software support, Wireless IR communication between shelves, Wireless RF (radio frequency) communication between shelves, Motor driver output for each shelf up to 4, Control via Android software (Can be used as a remote in mobile phone), Night mode, Authorization support,

Control and adjustment of rack numbering and sensors from the computer during installation,

Large size led information board per shelf, Operation and error records (200,000 operations).

Each rack is independent of the others and does not require an external PLC or panel, Only 1 feeder cable is used instead of hundreds of cables required in an application with an average of 10 racks, Collision-free accordion movement between racks, Industrial control for forklift operator use, In-house thanks to Ethernet connection access over the network or via wireless wifi. Warehouse management software support, Wireless IR communication between shelves, Wireless RF (radio frequency) communication between shelves, Motor driver output for each shelf up to 4, Control via Android software (Can be used as a remote in mobile phone), Night mode, Authorization support,

Control and adjustment of rack numbering and sensors from the computer during installation,

Large size led information board per shelf, Operation and error records (200,000 operations).

Each rack is independent of the others and does not require an external PLC or panel, Only 1 feeder cable is used instead of hundreds of cables required in an application with an average of 10 racks, Collision-free accordion movement between racks, Industrial control for forklift operator use, In-house thanks to Ethernet connection access over the network or via wireless wifi. Warehouse management software support, Wireless IR communication between shelves, Wireless RF (radio frequency) communication between shelves, Motor driver output for each shelf up to 4, Control via Android software (Can be used as a remote in mobile phone), Night mode, Authorization support,

Control and adjustment of rack numbering and sensors from the computer during installation,

Large size led information board per shelf, Operation and error records (200,000 operations).